Hardwood | How It's Made

Knowing how hardwood floors are constructed can be very advantageous. It enables you to understand the product’s materials right from the beginning. Remember that these are materials you will be living with, and on, should you choose to have our hardwood flooring installed in your home.

Hardwood sizes, species and types

- solid wood floors means 3/4" thick plank that is 2 1/4" wide

- classic strip wood floors mostly -random lengths from 12" – 84"

- most common species solid strip: red oak, white oak, maple, cherry, white ash, hickory or pecan

- 3 common types of wood floors: Engineered, Solid, and Longstrip Plank

Click on an image below for more information

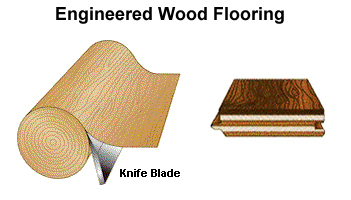

Type 1: Engineered

- made with 2,3, or 5 thin sheets laminated to form 1 plank

- plies stacked in opposite directions- cross-ply construction

- cross ply - dimensionally stable, less affected by moisture than 3/4” solid

- with moisture, solid planks expand across width not down length

- cross-ply advantage: plies counteract for plank growth, shrinking with humidity changes

- versatile: installed over concrete slabs or other places

- installed by: nailed down, stapled down, glued down, or floated

- over a wide variety of sub-floors, and some existing floors

- range: 1/4" to 9/16" thick

- width:2 1/4" to 7", mixed (3-5-7-inch planks installed side by side)

- varying widths can change the appearance

- lengths random: 12" – 60" in length

- made of layers - top finish layer is different species

- domestic or exotic species: Oak, Maple, Hickory or Cherry

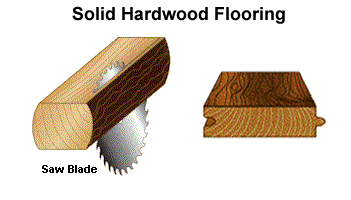

Type 2: Solid

- one solid piece with tongue and groove sides

- unfinished and pre-finished 3/4” solid

- moisture factor: sensitive to moisture

- used in nail down installations

- not recommended for below ground level, or over a concrete slab

- can be refinished, or recoated, several times

- natural product: expand and contract with season changes (moisture)

- in winter heating months, moisture leaves the wood causing contraction this creates gaps between planks

- in summer months, with high humidity, wood expands meaning gaps disappear

- too much moisture causes planks to cup, or buckle

- important to leave expansion around the perimeter

- important acclimate prior to installation

- Oak: used for solid unfinished floors - several qualities

to choose from

- clear-no visual blemishes or knots, expensive

- select and better- some small knots, little dark graining

- #1 common, #2 common - more knots and dark graining

Type 3: Longstrip

- similar to engineered floors

- several wood plies glued together

- center core is softer, used to make the tongue and groove with finish layer on top of the core

- top layer: any species made up of smaller individual pieces laid in 3 rows

- 86" in length and 7 1/2" in width

- 17 and 35 pieces making up the top layer of each board

- each plank looks like a section already pre-assembled

- designed for the floating installation

- can be glued-down, or stapled down

- extremely versatile – can go over a variety of sub-floors and grade level

- come in a wide variety of domestic and exotic species

- advantage: when damaged, they can be replaced easily